Colloidal Silica

Colloids are defined as a stable suspension of microscopic particles or molecules distributed throughout a second substance known as a dispersion medium. They differ from other types of suspensions in that the colloid is evenly dispersed throughout the suspension, and does not separate or settle. Colloids may be any combination of liquid, solid, and gaseous colloids and dispersion media.

Colloids are prevalent in a variety of common products and produced by various environmental and natural circumstances as well. They typically fall into one of the following categories:

- Liquid aerosols are made from liquid particles suspended in a gaseous dispersion medium, such as fog, mist, and hairspray.

- Solid aerosols are solids suspended in a gaseous dispersion medium. Common solid aerosols include smoke, dust, and air pollution.

- Liquid foams result from gas particles suspended in a liquid dispersion medium, such as whipped cream, shaving cream, and hair-styling mousse.

- Emulsion occurs when liquid particles are suspended in a liquid dispersion medium. Common examples include butter, hand lotion, and mayonnaise.

- Sol refers to solid particles suspended in a liquid dispersion medium. Pigmented ink, paint, and blood are common examples of sols.

- Solid foams are created when gas particles become suspended in a solid dispersion medium. Examples include Styrofoam, pumice, and plaster.

- Gels are made from solid particles suspended in a liquid dispersion medium. Gels are often treated in order to enhance the structure of the solid particles and create a more viscous solution. Gelatin and fruit jellies are common examples of gels.

- Solid sol refers to solid particles suspended in a solid dispersion medium, such as metal alloys, colored glass, and gemstones.

Colloidal silica consists of silica molecules suspended in liquid, thereby forming a liquid sol. The process of creating colloidal silica is closely monitored to ensure that the silica molecules remain stable and separate within the liquid medium without collapsing into smaller component molecules or collecting into unstable silica gels. The liquid dispersion medium exhibits greater density than water and must be electrostatically treated for enhanced ionic stabilization.

Colloidal silica is highly fluid with low viscosity. Uses for colloidal silica vary depending on the size of the silica particles in the solution and the modifiable pH, ionization, and surface charge.

Colloidal Silica Uses and Applications

Applications that use colloidal silica vary widely. It can be used to enhance or direct the movement of substances within various processes. For example, it is used in the paper manufacturing process to draw liquid from the finished paper quickly, thereby allowing the paper to dry faster while retaining its strengthening starch. Similarly, colloidal silica can be used to absorb moisture in industrial settings where moisture levels are high. Depending on the size of its constituent particles, colloidal silica may be used to enhance the movement of materials or to increase surface friction.

Colloidal silica is used in a broad range of industries and applications, including:

- Densification of concrete, cement, and other materials

- Fine retention in paper manufacturing

- Enhanced bonding of waterborne adhesives

- Improved surface friction and anti-slip properties

- Wastewater filtration flocculant

- Investment casting binding

- Anti-soilant textile coatings

- Anti-blocking aid for films

- Scratch resistant surface coatings

- Anionic coagulant

- Ceramic fiber binder and rigidizing agent

- Catalyst attrition resistance

- Abrasive polishing agent

- Strength-enhancing additive to plastics, mortar, and concrete

Colloidal Silica from Applied Material Solutions

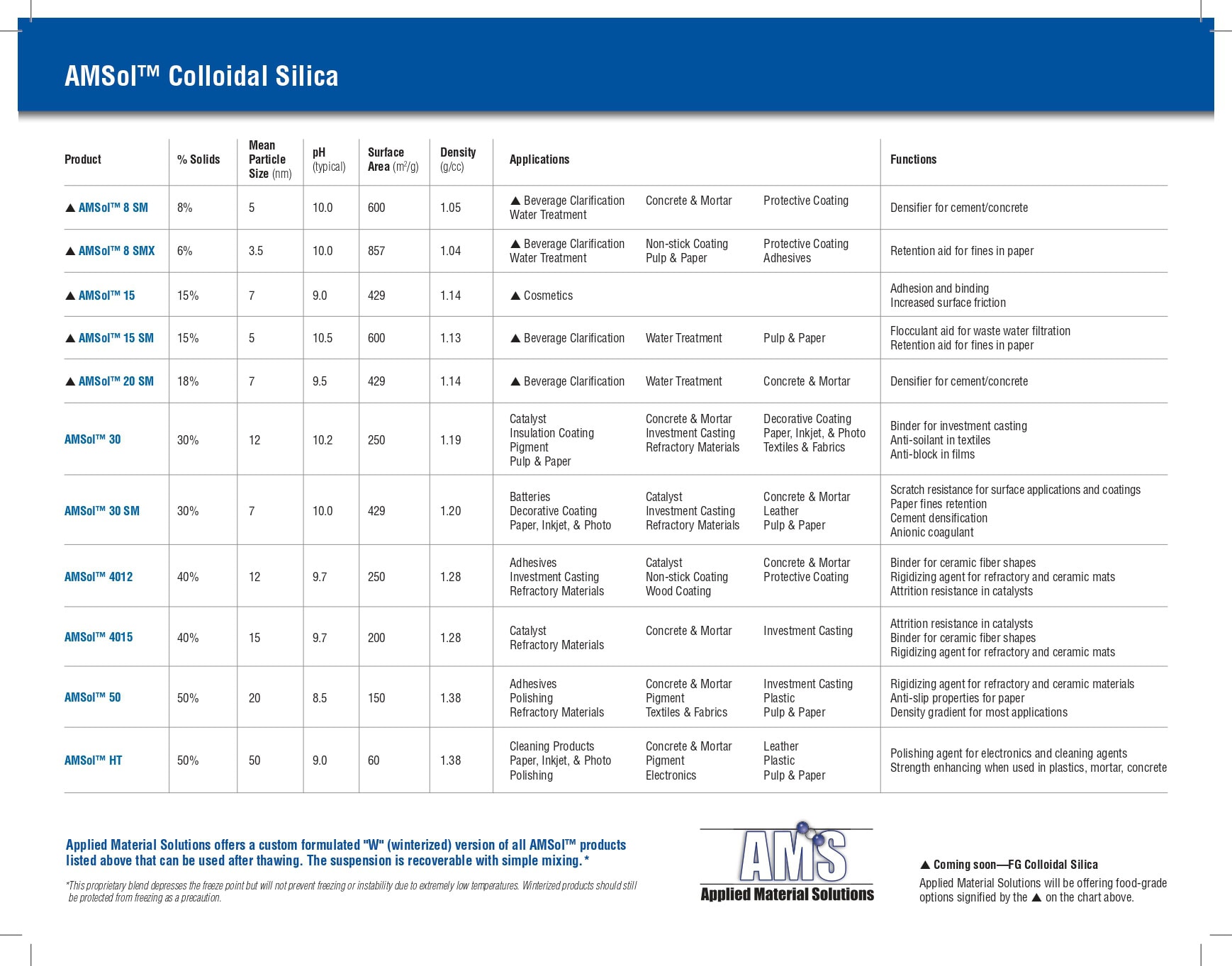

Applied Material Solutions is pleased to offer high-purity, customizable colloidal silica products that can be tailored to meet the specific needs of a variety of applications. Our proprietary manufacturing process produces a uniform distribution profile to ensure a low percentage of off-size particles and contaminants.

Our goal is to provide our partner companies with colloidal silica to match their specified requirements, while also offering controlled particle size distribution for consistent application performance.

Our products are available in a broad range of sizes, hydrophobicity levels, and surface areas. We are also pleased to offer products in winterized, food-grade, and technical-grade designs, to meet industry standards.

Applied Material Solutions offers a custom formulated “W” (winterized) version of all AMSol™ products listed above that can be used after thawing. The suspension is recoverable with simple mixing.*

*This proprietary blend depresses the freeze point but will not prevent freezing or instability due to extremely low temperatures. Winterized products should still be protected from freezing as a precaution.

In addition to our exceptional colloidal silica products, we offer an array of antifoam and defoaming products, hydrophobic treated silica, silicone emulsions, and toll manufacturing services.

AMSolTM Colloidal Silica

To learn how our state-of-the-art colloidal silica solutions can benefit your operation, contact us today.