The manufacturing of pulp and paper causes the formation of many chemicals like rosin, tall oil, and lignin—soaps that have a strong tendency to foam during the pulp and paper-making process. Foam negatively affects the washing efficiency and the manufacturing of pulp and paper, which leads to flaws in the finished sheet.

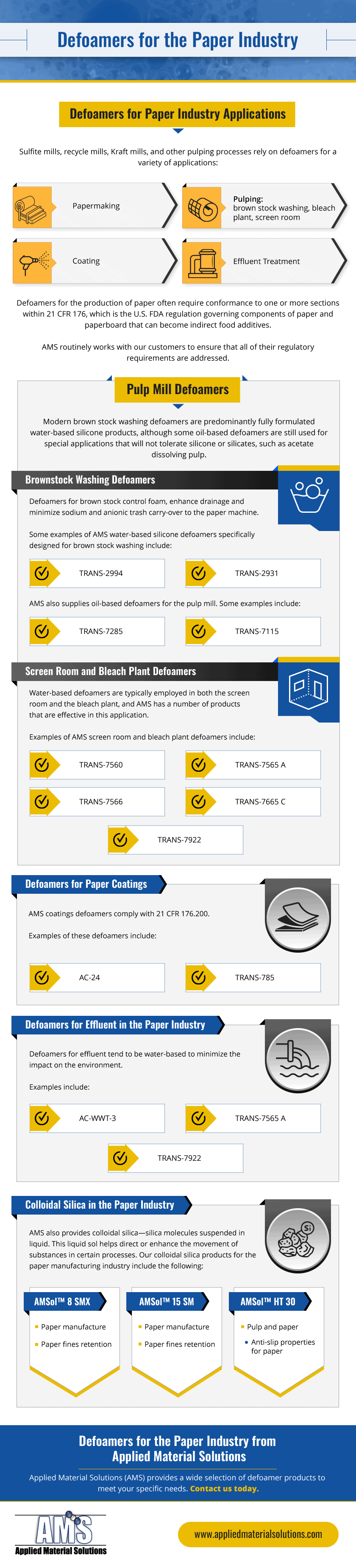

Defoamers for Paper Industry Applications

Sulfite mills, recycle mills, Kraft mills, and other pulping processes rely on defoamers for a variety of applications:

- Paper making

- Pulping: brown stock washing, bleach plant, screen room

- Coating

- Effluent treatment

Defoamers for the production of paper often require conformance to one or more sections within 21 CFR 176, which is the U.S. FDA regulation governing components of paper and paperboard that can become indirect food additives.

AMS is well-versed in matching a defoamer to its intended application, and we routinely work with our customers to ensure that all of their regulatory requirements are addressed. Whether you need to conform with 21 CFR 176.170, 180, 200, 210, or other paper regulations across the globe, such as German BfR, we’ve got you covered.

Contact us today and speak with an expert about selecting a defoamer for your exact set of requirements.

Defoamers for the Paper Industry: Pulp Mill Defoamers

Modern brown stock washing defoamers are predominantly fully formulated water-based silicone products, although some oil-based defoamers are still used for special applications that will not tolerate silicone or silicates, such as acetate dissolving pulp.

AMS manufactures an array of defoamers for the pulp mill, which includes brown stock washers, the screen room, and the bleach plant.

Brownstock Washing Defoamers

Defoamers for brown stock control foam, enhance drainage, and minimize sodium and anionic trash carry-over to the paper machine.

Some examples of AMS water-based silicone defoamers specifically designed for brown stock washing include:

- TRANS-2994

- TRANS-2931

AMS also supplies oil-based defoamers for the pulp mill. Some examples include:

- TRANS-7285

- TRANS-7115

Screen Room and Bleach Plant Defoamers

Water-based defoamers are typically employed in both the screen room and the bleach plant, and AMS has a number of products that are effective in this application.

Examples of AMS screen room and bleach plant defoamers include:

- TRANS-7560

- TRANS-7565 A

- TRANS-7566

- TRANS-7665 C

- TRANS-7922

Defoamers for the Paper Industry: Paper Machine Defoamers

Paper machine defoamers are typically water-based or glycol-based products but may include other chemistries. AMS designs its defoamers to have a minimal impact on sizing and a maximum reduction of entrained air.

TRANS-7664 is a water-based defoamer developed as a high-solids concentrate to minimize the shipping of water, which ultimately maximizes its economic benefit. It was designed to be received, or diluted with water prior to use (e.g. in-line dilution), and it requires minimal production equipment to dilute to lower concentrations. This makes it a great choice for resellers looking to add a high-performance, economical paper machine defoamer to their product line.

Effective to use in paper machines, in screen rooms, in effluent systems, or any application requiring a water-based defoamer, TRANS-7664 performs over a wide range of temperatures—up to 160 °F/71 °C—so it is effective in high-temperature applications that would prove too challenging for “run of the mill” water-based defoamers.

TRANS-3983 is an ester-based defoamer effective during wet strength runs and for fine paper, liner board, and corrugated media, and can often be utilized at significantly lower dosages compared to other defoamer chemistries.

Defoamers for Paper Coatings

AMS coatings defoamers comply with 21 CFR 176.200. Examples of these defoamers include:

- AC-24

- TRANS-785

Defoamers for Effluent in the Paper Industry

Defoamers for effluent tend to be water-based to minimize the impact on the environment.

Examples include:

- AC-WWT-3

- TRANS-7565 A

- TRANS-7665 C

Colloidal Silica in the Paper Industry

AMS also provides colloidal silica—silica molecules suspended in liquid. This liquid sol helps direct or enhance the movement of substances in certain processes. For example, colloidal silica can be used in paper manufacturing to extract liquid from the finished paper product more rapidly, letting the paper dry faster while retaining the paper’s strengthening starch content. Other applications include adding anti-slip properties or fine retention to paper in paper manufacturing processes.

Our colloidal silica products for the paper manufacturing industry include the following:

- AMSol™ 8 SMX

- Pulp and paper adhesives

- Retention aid for fines in paper

- AMSol™ 30

- Paper, inkjet, and photo

- Paper fines retention

- AMSol™ 50

- Pulp and paper

- Anti-slip properties for paper

- Pulp and paper

Defoamers for the Paper Industry from Applied Material Solutions

Quality defoamers for the paper industry help streamline manufacturing processes, improve final product quality, and meet all applicable regulatory requirements. Applied Material Solutions (AMS) provides a wide selection of defoamer products to meet your specific needs. Contact us today to learn how we can help with your facility’s defoamer challenges.