Emulsions are defined as a stable dispersion of two immiscible liquids. Emulsions are commonly formed during many industrial processes, occurring when water and oil become mixed together. In ethanol-producing dry mills, corn oil droplets become stabilized within the stillage, thereby making it harder to recover.

Since corn oil plays an important role in the profitability of fuel ethanol facilities, it is very important to find effective ways to maximize its recovery. One way to do this is by using demulsifiers.

Corn Oil Demulsifiers

Corn oil demulsifiers offer ethanol producers an extremely effective method for enhanced corn oil extraction. By improving oil release during the mechanical extraction process, corn oil demulsifiers significantly boost corn oil yields, which translates into increased profits. Not only do they enhance profitability, but corn oil demulsifiers can also improve corn oil quality.

How Do They Work?

Corn oil demulsifiers are feed-grade, surface-active materials that facilitate the breaking of the emulsion between the oil and water components of stillage (aka “syrup”).

Once the demulsifier penetrates the emulsion, it assists the oil droplets by helping them coalesce, thereby forming larger droplets. These bigger droplets are considerably easier to separate and collect via centrifugation, resulting in greater DCO (Distillers Corn Oil) yield. By modifying the surface chemistry within the stillage, oil is more easily released, resulting in increased oil yield.

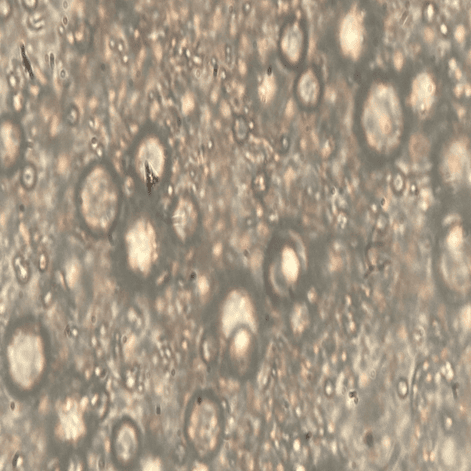

Oil Droplets After Evaporator

Oil Droplets Coalesce After Demulsifier Is Added

Oil Droplets Have Been Released After Centrifugation

AMulSion™ Corn Oil Separation Aids and their Benefits

AMS produces a wide range of corn oil separation aids, and we offer customized products to enhance the oil separation within your particular set of operating conditions.

Our AmulSion™ separation aids include:

AMulSion COD-206

AMulSion COD-8324

- Concentrated, workhorse demulsifiers effective across a broad range of working conditions.

AMulSion COD-711H

AMulSion COD-745

- Unique chemistry formulated with AMS-made hydrophobic silica.

- Delivers results where others fall short.

AMS corn oil separation aids offer the following advantages:

- Lowered demulsifier feed rate

- Reduced demulsifier costs

- Boosted corn oil yield

- Reduced solids for cleaner, high-quality oil

- Increased profits

- Effectiveness across a range of operating conditions

- Reliable and on-time delivery

Partnering with AMS

When you partner with AMS for high-quality emulsion breaker solutions, you gain access to the following:

- On-site testing support available

- Lab analysis of syrup

- Vertically integrated manufacturer of key demulsifier components, including hydrophobic silica

- Midwest manufacturing locations in close proximity to a majority of producers

- AMS also offers antifoams, defoamers, cleaning compounds and many other solutions.

Contact AMS Today

Emulsions pose a significant challenge to the extraction process of corn oil. Demulsifiers serve to simplify the separation process, resulting in increased corn oil yield and higher profits. At AMS, we offer various corn oil separation aids, and we can customize our products to meet your specific needs. To learn more about our line of AMulSion™ corn oil demulsifiers or to get started on your custom solution, contact us today.