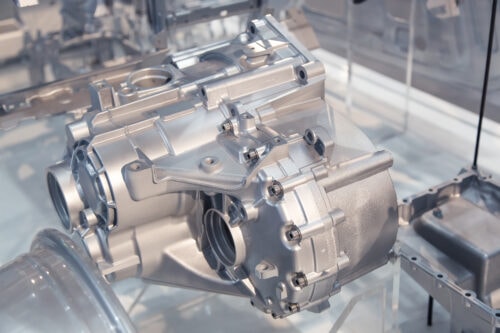

Die casting is an important industrial process used to manufacture high-precision metal parts. It involves injecting molten non-ferrous metal alloys into a die or mold. After some time, the molten alloy solidifies into a casting, which is removed. The mold is then reused for the next casting.

Die Lubricants

Die lubricants are specialty fluids that help provide lubrication for various steps of the die casting process. They can be engineered to provide quick and easy casting release, die/solder protection, rapid die surface cooling, smooth metal flow, and to maintain die temperatures within narrow ranges. All of these features help accelerate cycle times and extend die service life.

Die lubricants prevent solder by resisting thermal degradation in core pin, gate, and direct impingement areas of the die where high temperatures can cause the solder to form.

Features/Benefits

Our die lubricants offer a variety of benefits:

- The unique formulation offers excellent casting release and lubrication of ejector pins and sliding cores.

- They have a balanced mix of ingredients that produce stain-free, bright castings with an appealing, paintable finish.

- They prevent buildup on parting lines, spray heads, machine platens, and colder outer-cavity areas of the die.

- AMS high-performance die lubricants provide excellent die protection, higher dilution ratios, and lower on-line cost.

Plunger Lubricants

Plunger lubricants minimize the wear on the plunger tip and sleeve to increase its lifespan, minimize downtime, and improve casting quality. To prevent intensification pressure issues due to molten metal leaking around the plunger tip, plunger lubricants also serve as a seal. Our PLUNGER-MAXX 101B is a full-bodied, oil-based, graphite-free lubricant designed for plunger tip and shot sleeve lubrication in the cold-chambered, high-pressure casting of magnesium and aluminum alloys.

Features/Benefits

Plunger lubricants from AMS offer a range of advantages:

- As highly refined, petroleum-based oils, they wet and spread quickly for maximum coverage.

- Appropriate viscosity offers excellent protection against shot sleeve and plunger tip wear.

- They produce minimal smoke and gas, hence reducing porosity generation.

- Special additive package synergizes with DIE-MAXX die lubricants, enhancing casting release.

High-Quality Die Lubricants and Plunger Lubricants From AMS

Die casting is an important process that helps create metal parts for critical applications. At Applied Material Solutions, we supply plunger and die lubricants, which help minimize friction and enhance the longevity of dies and molds. We also provide colloidal silica, defoamer and antifoam products, silicone emulsions, hydrophobic treated silica, and toll manufacturing.

Contact us today for more information about our products or capabilities.