Many different types of municipal and industrial water treatment applications are prone to air entrainment and foaming, and industries as varied as food processing plants, refineries, and paper mills typically require antifoams for their wastewater. Excessive foam that is not under control can slow down, stall, or outright stop your operation, and can rapidly become costly. Airborne or waterborne foam in the environment can create public relations problems, and uncontained foam can create hazardous situations including slippery conditions, visual obstruction, as well as the unwanted transport of microorganisms or chemicals where they don’t belong.

Whether your foaming problem is associated with biological macromolecules (proteins and polysaccharides) originating from microbial metabolism, or surfactant contamination from industrial cleaning compounds and chemicals, or your company’s own product (or any combination thereof), AMS’s extensive line of antifoam products is well positioned to bring your foam under control. We offer broad-spectrum antifoams capable of addressing foam in highly variable systems, as well as specialized chemistries designed to destroy foam under very specific conditions.

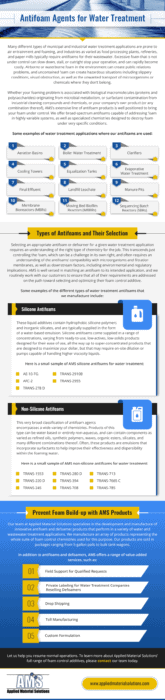

Some examples of water treatment applications where our antifoams are used:

- Aeration Basins

- Boiler Water Treatment

- Clarifiers

- Cooling Towers

- Equalization Tanks

- Evaporative Water Treatment

- Final Effluent

- Landfill Leachate

- Manure Pits

- Membrane Bioreactors (MBRs)

- Moving Bed Biofilm Reactors (MBBRs)

- Sequencing Batch Reactors (SBRs)

Types of Antifoams and Their Selection

Selecting an appropriate antifoam or defoamer for a given water treatment application requires an understanding of the right type of chemistry for the job. This transcends just controlling the foam, which can be a challenge in its own right, and often requires an understanding of the antifoams’ compatibility with microorganisms and filtration membranes, as well as downstream factors, including environmental and regulatory implications. AMS is well versed in matching an antifoam to its intended application, and we routinely work with our customers to ensure that all of their requirements are addressed on the path toward selecting and optimizing their foam control additive.

Some examples of the different types of water treatment antifoams that we manufacture include:

Silicone Antifoams

These liquid additives contain hydrophobic silicone polymers and inorganic silicates, and are typically supplied in the form of a water-based emulsion. Silicone antifoams come supplied in a range of concentrations, varying from ready-to-use, low-actives, low-solids products designed for their ease of use, all the way up to super-concentrated products that are designed to maximize your dollar, but that may require on-site dilution or pumps capable of handling higher viscosity liquids.

Here is a small sample of AMS silicone antifoams for water treatment:

- AE-10-TG

- AFC-2

- TRANS-278 D

- TRANS-2910B

- TRANS-2955

Non-Silicone Antifoams

This very broad classification of antifoam agents encompasses a wide variety of chemistries. Products of this type can be water-based or entirely non-aqueous, and can contain components as varied as refined oils, synthetic polymers, waxes, organic esters, silicates, and many different combinations thereof. Often, these products are emulsions that incorporate surfactants to help improve their effectiveness and dispersibility within the foaming water.

Here is a small sample of AMS non-silicone antifoams for water treatment:

- TRANS-1553

- TRANS-220 D

- TRANS-245

- TRANS-280 D

- TRANS-394

- TRANS-708

- TRANS-713

- TRANS-7665 C

- TRANS-785

Prevent Foam Build-up with AMS Products

Our team at Applied Material Solutions specializes in the development and manufacture of innovative antifoam and defoamer products that perform in a variety of water and wastewater treatment applications. We manufacture an array of products representing the whole suite of foam control chemistries used for this purpose. Our products are sold in packages ranging from 5-gallon pails to bulk tank wagons.

In addition to antifoams and defoamers, AMS offers a range of value-added services, such as:

- Field support for qualified requests

- Private labeling for water treatment companies reselling defoamers

- Drop shipping

- Toll manufacturing

- Custom formulation

Let us help you resume normal operations. To learn more about Applied Material Solutions’ full range of foam control additives, please contact our team today.