Food processors and agribusiness facilities must manage numerous conditions that cause or contribute to foam formation and air entrainment within their processes and products, including such things as high pressures, intense mixing and agitation, chemical reactions, gas formation, cell lysis, and impurities. These conditions often generate elevated levels of starch, protein, and/or other organic compounds that can rapidly create problematic foaming events.

Excessive levels of foam can lead to a host of adverse effects on facility operations, such as:

- Product defects or quality issues

- Slowed or stalled processing times

- Overflowing tanks, flumes, packaging and trucks

- Pump cavitation issues and equipment malfunction

- Inefficient or incorrect container-filling

- Unsafe workplace hazards

To prevent these risks and control costs, facility managers in the food processing and agribusiness industries leverage a wide array of antifoam agents. As one of the nation’s leading producers of food-grade antifoams, Applied Material Solutions (AMS) helps food processors find the best foam control products to optimize their process efficiency and product quality.

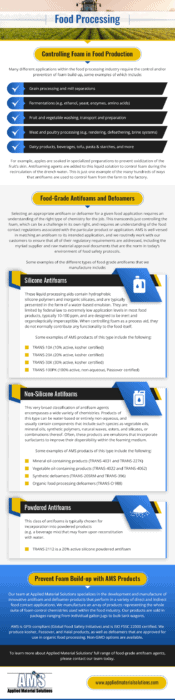

Controlling Foam in Food Production

Many different applications within the food processing industry require the control and/or prevention of foam build-up, some examples of which include:

- Grain processing and mill separations

- Fermentations (e.g. ethanol, yeast, enzymes, amino acids)

- Fruit and vegetable washing, transport and preparation

- Meat and poultry processing (e.g. rendering, defeathering, marinades)

- Dairy products, beverages, brine systems, and more

For example, apples are soaked in specialized preparations to prevent oxidization of the fruit’s skin. Antifoaming agents are added to this liquid solution to control foam during the recirculation of the drench water. This is just one example of the many hundreds of ways that antifoams are used to control foam from the farm to the factory.

Food-Grade Antifoams and Defoamers

Selecting an appropriate antifoam or defoamer for a given food application requires an understanding of the right type of chemistry for the job. This transcends just controlling the foam, which can be a challenge in its own right, and requires an understanding of the food contact regulations associated with the particular product or application. AMS is well versed in matching an antifoam to its intended application, and we routinely work with our customers to ensure that all of their regulatory requirements are addressed, including the myriad supplier and raw material approval documents that are the norm in today’s environment of food safety protocols.

Some examples of the different types of food-grade antifoams that we manufacture include:

- Silicone Antifoams: These liquid processing aids contain hydrophobic silicone polymers and inorganic silicates, and are typically presented in the form of a water-based emulsion. They are limited by federal law to extremely low application levels in most food products, typically 10-100 ppm, and are designed to be inert and organoleptically imperceptible. When controlling foam as a process aid, they do not normally contribute any functionality to the food itself.Some examples of AMS products of this type include the following:

- TRANS-10A (10% active, kosher certified)

- TRANS-20A (20% active, kosher certified)

- TRANS-30K (30% active, kosher certified)

- TRANS-100PK (100% active, non-aqueous, Passover certified)

- Non-Silicone Antifoams: This very broad classification of antifoam agents encompasses a wide variety of chemistries. Products of this type can be water-based or entirely non-aqueous, and usually contain components that include such species as vegetable oils, mineral oils, synthetic polymers, natural waxes, esters, and silicates, or combinations thereof. Often, these products are emulsions that incorporate surfactants to improve their dispersibility within the foaming medium. Some examples of AMS products of this type include the following:

- Mineral oil-containing products (TRANS-4031 and TRANS-227K)

- Vegetable oil-containing products (TRANS-400 and TRANS-4062)

- Synthetic polymer defoamers (TRANS-205RM and TRANS-396)

- Organic food processing defoamers (TRANS-O 580)

- Powdered Antifoams: This class of antifoams is typically chosen for incorporation into powdered products (e.g. a beverage mix) that may foam upon reconstitution with water.

- TRANS-2112 is a 20% active silicone powdered antifoam

If you would like to find out more about food-grade defoamers, watch this short video:

Prevent Foam Build-up with AMS Products

Our team at Applied Material Solutions specializes in the development and manufacture of innovative antifoam and defoamer products that perform in a variety of direct and indirect food contact applications. We manufacture an array of products representing the whole suite of foam control chemistries used within the food industry. Our products are sold in packages ranging from individual gallon jugs to bulk tank wagons.

AMS is GFSI-compliant (Global Food Safety Initiative) and is ISO FSSC 22000 certified. We produce kosher, Passover, and Halal products, as well as defoamers that are approved for use in organic food processing. Non-GMO options are available.

To learn more about Applied Material Solutions’ full range of food-grade antifoam agents, please contact our team today.