Many different types of municipal and industrial water treatment applications are prone to air entrainment and foaming, and industries as varied as food processing plants and refineries typically require antifoams for their wastewater. Antifoams for the paper industry are also common. Excessive foam that is not under control can slow down, stall, or outright stop your operation and can rapidly become costly. Airborne or waterborne foam in the environment can create public relations problems, and uncontained foam can create hazardous situations including slippery conditions, visual obstruction, as well as the unwanted transport of microorganisms or chemicals where they don’t belong.

Defoamers for Water Treatment Applications

Whether your foaming problem is associated with biological macromolecules (proteins and polysaccharides) originating from microbial metabolism, surfactant contamination from industrial cleaning compounds and chemicals, or your company’s own product (or any combination thereof), AMS’s extensive line of antifoam and defoamer products is well positioned to bring your foam under control. We offer broad-spectrum antifoams capable of addressing foam in highly variable systems, as well as specialized chemistries designed to destroy foam under very specific conditions.

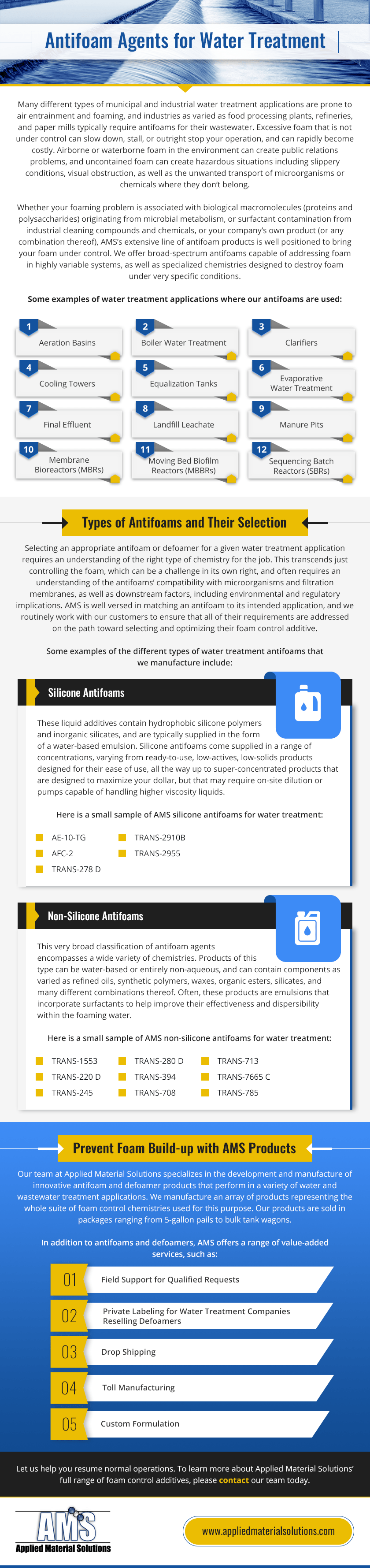

Some examples of water treatment applications using our antifoams and defoamers include:

- Aeration Basins. Also known as aeration lagoons, these holding or treatment locations allow for artificial aeration in secondary treatment processes. Our antifoams and defoamers address excessive foam buildup to facilitate oxygen uptake and discourage sludge formation in aerobic processes.

- Boiler Water Treatment. Systems for boiler water treatment chemically alter or eliminate foam-generating substances in boilers, as foam negatively impacts performance. These systems utilize antifoam and defoamer agents like water-soluble synthetic polymers to help water treatment chemicals within the boiler to achieve this in high-temperature environments.

- Clarifiers. These primary and secondary settling tanks serve to eliminate suspended solids or solid particulates from liquids and treated waste. The high solid content in secondary clarifiers can lead to foam formation and reduced efficiency, which our antifoam and defoamer products help prevent.

- Cooling Towers. This equipment effectively lowers the temperature of process and wastewater within manufacturing operations. The treatment chemicals that cooling towers use to enable this, however, can lead to concentrations of solids and then foam. Antifoam and defoamer products safeguard against this.

- Equalization Tanks. Such water tanks provide a consistent rate of flow for downstream water treatment processes and aerobic degradation. Foam will often form during aeration and agitation processes, given the impurities within the tanks’ water. Antifoams and defoamers work to minimize this.

- Evaporative Water Treatment. In evaporative water treatments, foam will negatively impact process efficiency. Our products reduce or prevent the existence of foam in treatment systems.

- Final Effluent. Processing systems for final effluent are utilized just before the completion of wastewater treatments. Water-based defoamers and antifoams, along with biodegradable and low-aquatic-toxicity components, reduce the chance of foam at the receiving waterway or outfall point.

- Landfill Leachate. Systems that treat landfill leachate must handle organic and inorganic matter that’s harmful to the environment and human health. Leachate treatment can generate foam, so antifoams and defoamers help lessen foam production.

- Manure Pits. Foam within manure pits can be particularly dangerous, as it traps biogas within. Antifoams and defoamers reduce the chance of explosion or gas ignition when used along with mechanical and biological treatment solutions.

- Membrane Bioreactors (MBRs). These membrane systems generate disinfected, clarified water by eliminating dissolved solids from the liquid. Membrane-compatible antifoams and defoamers combat foam production in MBRs.

- Moving Bed Biofilm Reactors (MBBRs). Incorporating both fixed film and activated sludge procedure principles, these reactors carry out a continuous flow, complete mix water treatment process. Filaments often develop within the biomass, resulting in foam that antifoams and defoamers can help address.

- Sequencing Batch Reactors (SBRs). Used in the treatment of wastewater, SBRs are fill-and-draw activated sludge systems in which wastewater enters a batch reactor, has the unwanted particulates removed, and then gets expelled. Antifoams and defoamers help deal with foam-producing non-degraded organic matter within the wastewater.

Types of Defoamers for Water Treatment

Selecting an appropriate defoamer or antifoam for a given water treatment application requires an understanding of the right type of chemistry for the job. This transcends just controlling the foam, which can be a challenge in its own right, and often requires an understanding of the antifoam’s compatibility with microorganisms and filtration membranes, as well as downstream factors, including environmental and regulatory implications. AMS is well versed in matching an antifoam to its intended application, and we routinely work with our customers to ensure that all of their requirements are addressed on the path toward selecting and optimizing their foam control additive.

Some examples of the different types of water treatment antifoams and defoamers that we manufacture include:

Silicone Defoamers for Water Treatment

These liquid additives contain hydrophobic silicone polymers and inorganic silicates, and are typically supplied in the form of a water-based emulsion. Silicone antifoams and defoamers come supplied in a range of concentrations, varying from ready-to-use, low-actives, low-solids products designed for their ease of use all the way up to super-concentrated products that are designed to maximize your dollar, but that may require on-site dilution or pumps capable of handling higher-viscosity liquids.

Here is a small sample of AMS silicone antifoams for water treatment:

- AE-10-TG

- AFC-2

- TRANS-278 D

- TRANS-2910B

- TRANS-2955

Non-Silicone Defoamers for Water Treatment

This very broad classification of defoamer and antifoam agents encompasses a wide variety of chemistries. Products of this type can be water-based or entirely non-aqueous, and can contain components as varied as refined oils, synthetic polymers, waxes, organic esters, silicates, and many different combinations thereof. Often, these products are emulsions that incorporate surfactants to help improve their effectiveness and dispersibility within the foaming water.

Here is a small sample of AMS non-silicone products for water treatment:

- TRANS-1553

- TRANS-220 D

- TRANS-245

- TRANS-280 D

- TRANS-394

- TRANS-708

- TRANS-713

- TRANS-7665 C

- TRANS-785

Defoamers for Water Treatment From Applied Material Solutions

Defoamers and antifoams for water treatment effectively reduce or eliminate foam to safeguard system efficiency and performance. If you’re looking for an antifoam or defoamer for water treatment, the experts at AMS can help you select the optimal solution from our diverse product line. As a leading manufacturer of foam control products, colloidal and hydrophobic silicas, silicone emulsions, corn oil demulsifiers, die cast lubricants, and related chemical products, we’ve spent the last 45 years serving industries ranging from water treatment to pulp and paper processing with our proprietary manufacturing procedures.

To learn more about our antifoams and defoamers for water treatment, contact us today.