Applied Material Solutions offers a variety of industrial chemical products. In addition to colloidal silica, we provide a selection of antifoams and defoamers, hydrophobic treated silica, and toll manufacturing services. You’ll find our headquarters in Elkhorn, WI, while Burlington, WI, and Rockton, IL, are home to our manufacturing plants.

Here you’ll learn the differences between fumed silica and colloidal silica, which are otherwise identical at the molecular level. While AMS is a manufacturer of colloidal silica, we are not outright a manufacturer of fumed silica. Instead, we take fumed silica and surface-treat it with silicone polymers to make it hydrophobic.

What Is Colloidal Silica?

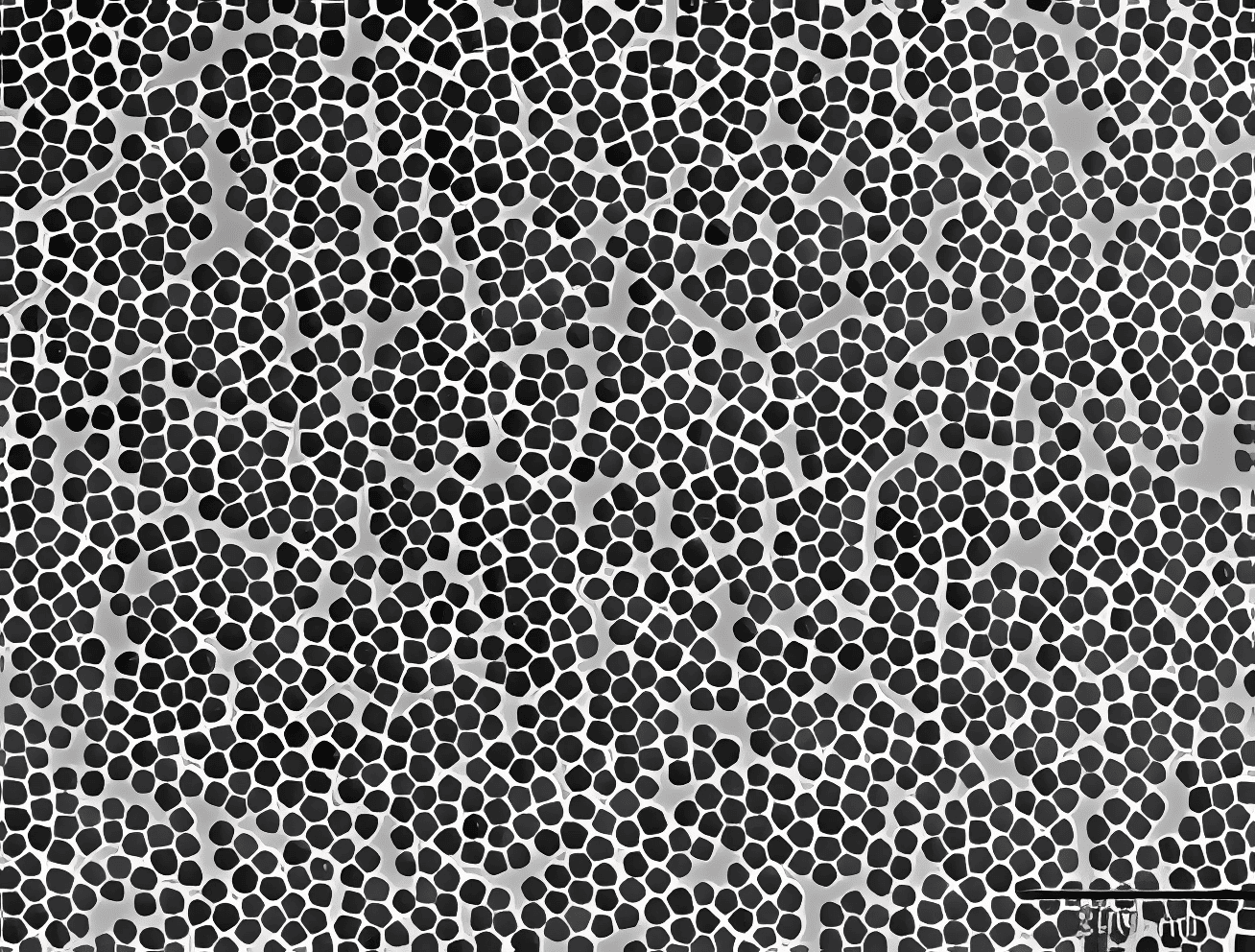

Colloidal silica is a water-based, stabilized dispersion of amorphous silicon dioxide (aka silica) nanoparticles. Manufacturers produce colloidal silicathrough the polymerization of silica nuclei derived from silicate solutions. Polymerized under alkaline conditions, the silica nuclei convert into silica sols (solid particles) at the nano-scale and with a high surface area. The process then applies a charge to these silica sols, causing electrostatic resistance between each particle and creating a colloid—a type of stable dispersion.

These microscopic colloids remain suspended in a dispersion medium, typically water. What makes colloids different from other suspensions is their even distribution, without settling or separating. Colloids can be comprised of many types of solid, gaseous, and liquid substances within a dispersion media. In the case of colloidal silica, the colloid is a microscopic solid dispersed in water.

What Is Fumed Silica?

Fumed silica is an amorphous, nano-scale, powdered material. Fumed silica particles are formed by injecting air and hydrogen flames with silicon tetrachloride or other types of chlorosilanes. Like colloidal silica, fumed silica particles are extremely small and have large surface areas. Furthermore, fumed silica particles have the same molecular composition as colloidal silica particles, except that they are presented in powdered form as opposed to a stabilized liquid dispersion.

What Are the Applications of Fumed Silica and Colloidal Silica?

Fumed silica functions as a desiccant that thickens various substances. For example, food manufacturers may use it to thicken liquid food products or prevent caking in powdered products. Other potential applications for fumed silica include cosmetics, toothpaste, and fillers in silicone elastomers. It also adjusts viscosity, alters rheology and modifies the physical characteristics of paints, coatings, adhesives and sealants.

Similar to fumed silica, applications for colloidal silica include absorbing moisture in industrial settings with high moisture levels. Colloidal silica is also used to increase surface friction, facilitate the movement of materials, and as a binding agent.

Attributes of Fumed Silica and Colloidal Silica

| Typical Attributes | Colloidal Silica | Fumed Silica |

| Physical State | Liquid | Powder |

| Concentration | Variable - Often 6% - 50% | Typically 100% |

| Creation | Nucleation Reaction | Flame Hydrolysis |

| Common Applications | Binder, Densifier, Coagulant | Thickener, Stabilizer, Rheology Control |

| Particle Size | Variable - Often 3 nm - 50 nm | Variable - e.g. 5 nm - 20 nm |

| Surface Area | Variable - Often 60 - 1,000 m2 /g | Variable - e.g. 100 - 200 m2 /g |

| Hydrophilic vs Hydrophobic | Both. AMS manufactures hydrophilic colloidal silica. | Both. AMS manufactures hydrophobic fumed silica. |

Silicates From Applied Material Solutions

When selecting a colloidal silica or hydrophobic fumed silica, turn to Applied Material Solutions. We offer a wide variety of colloidal silica options, including winterized versions, and a versatile fumed silica in the form of our AMSil-F H22.

For more information about our silica products and other solutions, contact Applied Material Solutions today or call our offices at 262-723-6595.

Comments are closed