Foam is a major challenge to fluid systems. It can reduce product quality, significantly disrupt system efficiency, and even create safety risks if left untreated. While pure liquids do not foam, the presence of any proteins, surfactants, or particulates can cause bubbles to form quickly. Adding an antifoaming agent to points of agitation destabilizes foam film and prevents bubble formation, preventing issues like overflow, equipment blockages, and corrosion.

What Is an Antifoam?

An antifoam is a chemical additive used to prevent foam from forming in fluid systems. It works by reducing surface tension and film elasticity to prevent bubbles from forming. Antifoam agents are defined by a few key characteristics:

- Immediate action. Antifoams enter bubble walls and weaken them by displacing foam-stabilizing surfactants. They collapse bubbles on contact, causing foam to disappear rapidly.

- Insolubility. Antifoams do not dissolve in liquid. Instead, their relative insolubility allows them to migrate and reside at a fluid medium’s surface and remain effective.

- Low surface tension. Due to their low surface tension, antifoaming agents rapidly spread across a fluid’s surface and remain active at the site of bubble formation.

- Dispersible particles. Many antifoam formulations include hydrophobic solids, such as fatty acids, silica, or waxes. These substances are dispersed for improved foam-breaking capabilities.

How Do Antifoaming Agents Work?

Foam forms when gases become entrapped in a process liquid and are stabilized by the presence of surface-active materials. These substances create elastic films around bubbles, allowing them to remain present even under agitation. Antifoaming agents work by disrupting these stabilizing films as they form, whereas a defoamer destroys existing foam buildup. However, some antifoaming technologies offer both capabilities.

Due to their low surface tension and insolubility, antifoams spread rapidly, destroying film elasticity, causing bubbles to burst. By breaking down foam as it develops, antifoaming agents prevent bubbles from building to problematic levels, ensuring processes run efficiently.

Benefits of Antifoam

Antifoam agents offer many benefits beyond basic foam control. Some of the biggest advantages of incorporating antifoaming agents into industrial processes include:

Reducing operation costs. Antifoam agents eliminate the product loss caused by foam overflows, minimize wasted materials, and eliminate unplanned downtime for overflow cleaning.

Extending equipment lifespan. The presence of foam can lead to corrosion and wear on machinery, pumps, and pipes, which antifoams help to prevent. Antifoam agents can also help you avoid costly process interruptions, like pump cavitation, flow blockages, or overfilling.

Maintaining regulatory compliance. In many industries, maintaining low foam levels is a compliance requirement. Antifoam agents help to eliminate cross contamination and workplace safety hazards that can occur as a result of foam spills, like slipping or product contamination, maintaining proper safety as well as quality standards.

Uses Across Industries

Antifoaming agents are essential to many industries. At AMS, we offer food-grade and tech-grade antifoams for numerous industries, including:

- Food processing. Manufacturing food products can create foam throughout multiple production stages, slowing down production or resulting in diminished product quality. Our solutions prevent foam formation and combat existing foam buildup.

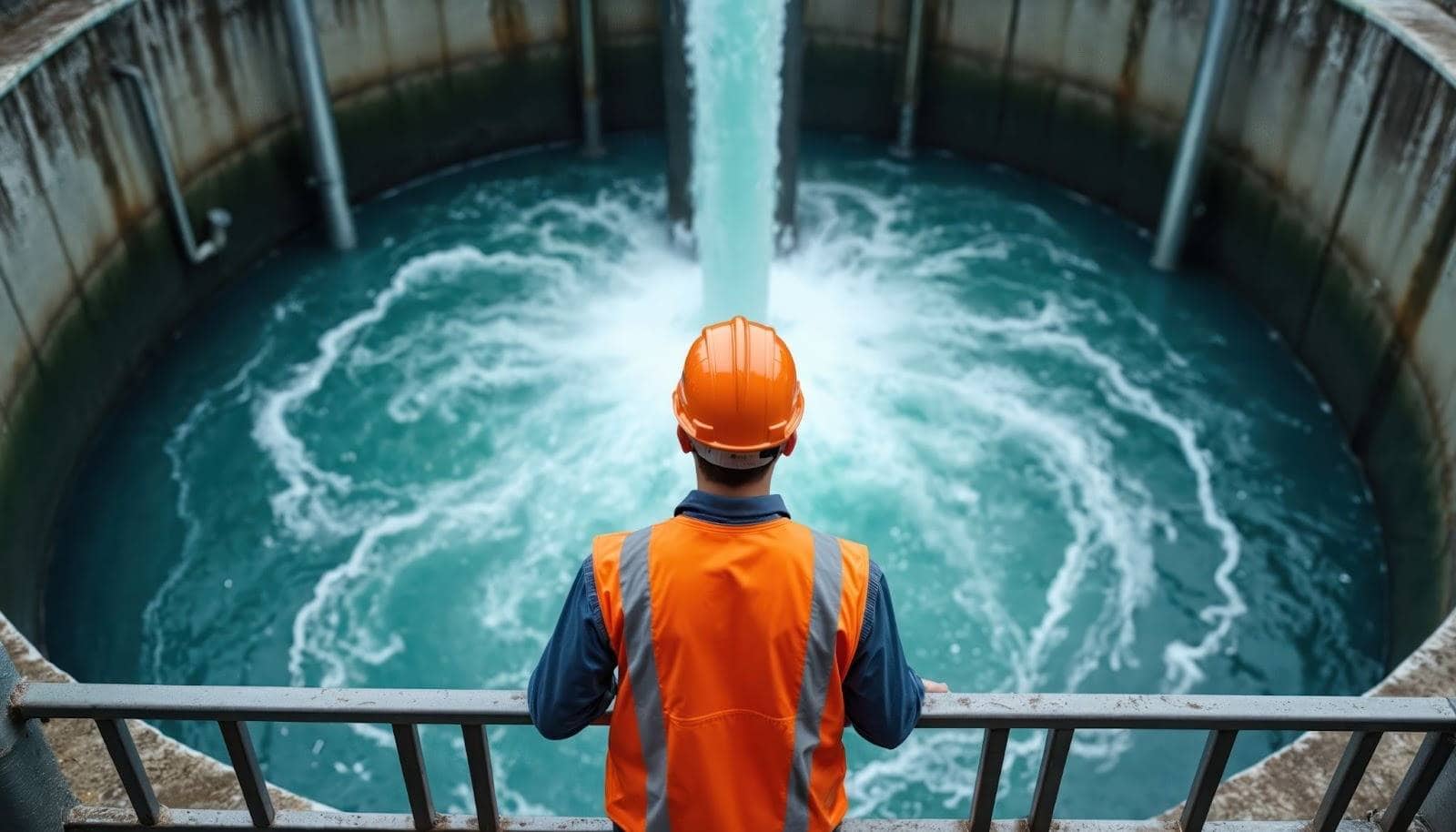

- Water treatment. Foam is common in many water treatment processes and can result in water not being able to pass through filtration systems.

- Fuel ethanol production. In wet mill operations, foam negatively impacts operations, harming fermentation and distillation. Antifoam products from AMS are customized to the needs of each plant and feature additives that have been trusted by clients for over 40 years.

- Paper manufacturing. Many byproducts of mills and pulping operations create foam, resulting in inefficient production and lower-quality products. Antifoam agents eliminate these and related challenges.

- Paints, inks, coatings, and adhesives. Without antifoam agents, the manufacturing process for paints, inks, and adhesives creates foam that negatively impacts production time.

Antifoaming Agents From AMS

Applied Material Solutions offers an extensive selection of high-quality, American-made antifoam agents, including specialized formulas tailored to industry-specific needs. Our facilities are ISO 9001:2015, ISO FSSC 22000, and GFSI certified and equipped with best-in-class technology.

If your process is experiencing problems with foam formation, our experts are here to help. Contact us today for expert guidance on selecting the antifoaming agent for your application.