Brown stock washing is a complex, dynamic process in which dirty wash water or weak black liquor (dissolved organic and inorganic material obtained from the pulp cooking process) is separated from the pulp fibers1. The organic materials are recovered for their fuel value and the inorganic material is recovered for the sodium content to regenerate NaOH.

Under-designed capital equipment can be augmented using chemical enhancements. In the case of brownstock washers, the application of defoamer is required to improve mat drainage and to control foam to enable overloaded washers to wash efficiently; this also allows pulp from the digesters to flow continuously to the bleach plant and/or the paper machine.2

Washing efficiency directly correlates to pulp cleanliness. Cleaner pulp results in better chemical recovery, lower bleaching costs, fewer deposition issues, and more consistent pulp is sent to the paper machine.

The following article provides an overview of brown stock washing deformers, outlining how they work, key benefits, and the types available.

How Do Brown Stock Washing Defoamers Work?

Brown stock washing defoamers have two purposes. First is to control the foam and prevent vats from overflowing onto the floor causing loss of product (the pulp) and housekeeping issues, while providing drainage on the washers which provides cleaner pulp and improves washing efficiency.

Second is to recover valuable spent liquor. The black liquor is recovered for the fuel value and to regenerate NaOH by recovering sodium from the washing process.

The foam level in the vat is not an indication of how well the defoamer is performing. If the foam is not spilling over on to the floor it is then purely cosmetic. The real indication of the defoamer’s performance is how well the foam is being released from the fiber. When the foam is released from the fiber it allows drainage.

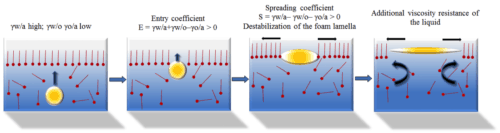

It is important to understand the defoamer must have a positive Entry Coefficient and a positive Spreading Coefficient. These are expressed in the following equations:

(Entry Coefficient) E = γw/a + γw/o – γo/a

Where γ is the surface tension or interfacial tension in dynes/cm2

(Spreading Coefficient) S = γw/a – γw/o – γo/a

Where “w” is water, “o” is oil, and “a” is air

The equations briefly explained:

The Entry Coefficient is equal to the surface tension of the black liquor + the interfacial tension between liquor and oil (i.e. the defoamer), minus the surface tension of the oil. This allows the defoamer droplet to enter the monolayer at the air/water interface.

The same is true for the Spreading Coefficient: black liquor – the interfacial tension between liquor and oil, minus the surface tension of the oil. This causes the defoamer droplet to spread along the air/water interface forming a defoamer “lens.”

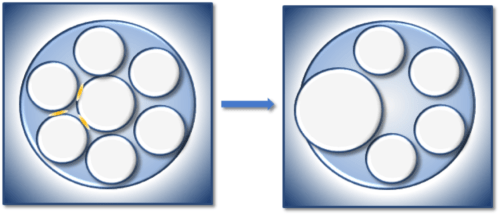

On fiber, larger and larger bubbles are formed until the buoyancy of the bubble overcomes its adherence to the fiber and floats away from the fiber. The foam on the fiber causes an apparent increase in the fiber’s size. As the foam is removed from the fiber the apparent fiber size decreases creating a shorter path for the water to travel through the mat. The shorter path for the water results in improved drainage.

It should be noted, when using defoamers in brown stock washing operations, it is important to understand that the defoamer must perform a balancing act, where the defoamer is sufficiently compatible in the black liquor to not cause deposition, yet incompatible (insoluble) enough to perform efficiently on the washer. A defoamer is never soluble in the medium it is defoaming.

Benefits of Brown Stock Washing Defoamers

A good defoamer program should facilitate production of the pulp, and add economic value to the pulp mill process by addressing the following:

- Housekeeping issues

- Increased chemical recovery

- Reduced energy costs

- Lower bleaching costs

- The reduction of the environmental impact of the mill

- Fewer safety hazards

- Increased production rates

- Increased quality of the end product

- Lower reject rates3

Types of Defoamers for Brown Stock Washing Operations

- Oil-based defoamers

- Water-extended, oil-based defoamers

- Concentrated or water-based silicone defoamers

- Polymer-based defoamers

Oil-based and water-extended oil-based defoamers are less common than they were 15 to 20 years ago. They are used primarily in mills where silicone and/or silicates are not allowed.

Brown Stock Washing Defoamer Solutions From AMS

Brown stock washing defoamers are essential to both product and process quality. As a leading manufacturer and supplier of foam control products, Applied Materials Solutions has an extensive range of products suitable for use in these pulping applications. Our product offerings include:

- Water-based silicone defoamers: (e.g. TRANS-2994 and TRANS-2931)

- Oil-based defoamers: (e.g. TRANS-7285 and TRANS-7115)

For additional information about our brown stock washing defoamers and other product solutions, contact us today.

References

Brownstock washing – A review of the literature, TAPPI Journal January 2014, Ricardo B. Santos and Peter W. Hart; page 9

Brownstock Washing – Practices and Fundamentals. TAPPI Press, Peter Hart and Michael Brown, Chapter 15, page 545

Brownstock Washing – Practices and Fundamentals. TAPPI Press, Peter Hart and Michael Brown, Chapter 15, page 562

Comments are closed