Industrial-Grade Defoamers

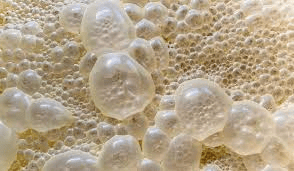

Defoamers are chemical agents that knock down and reduce foam produced during industrial processes, including applications as varied as detergent manufacture and in effluent systems. […]

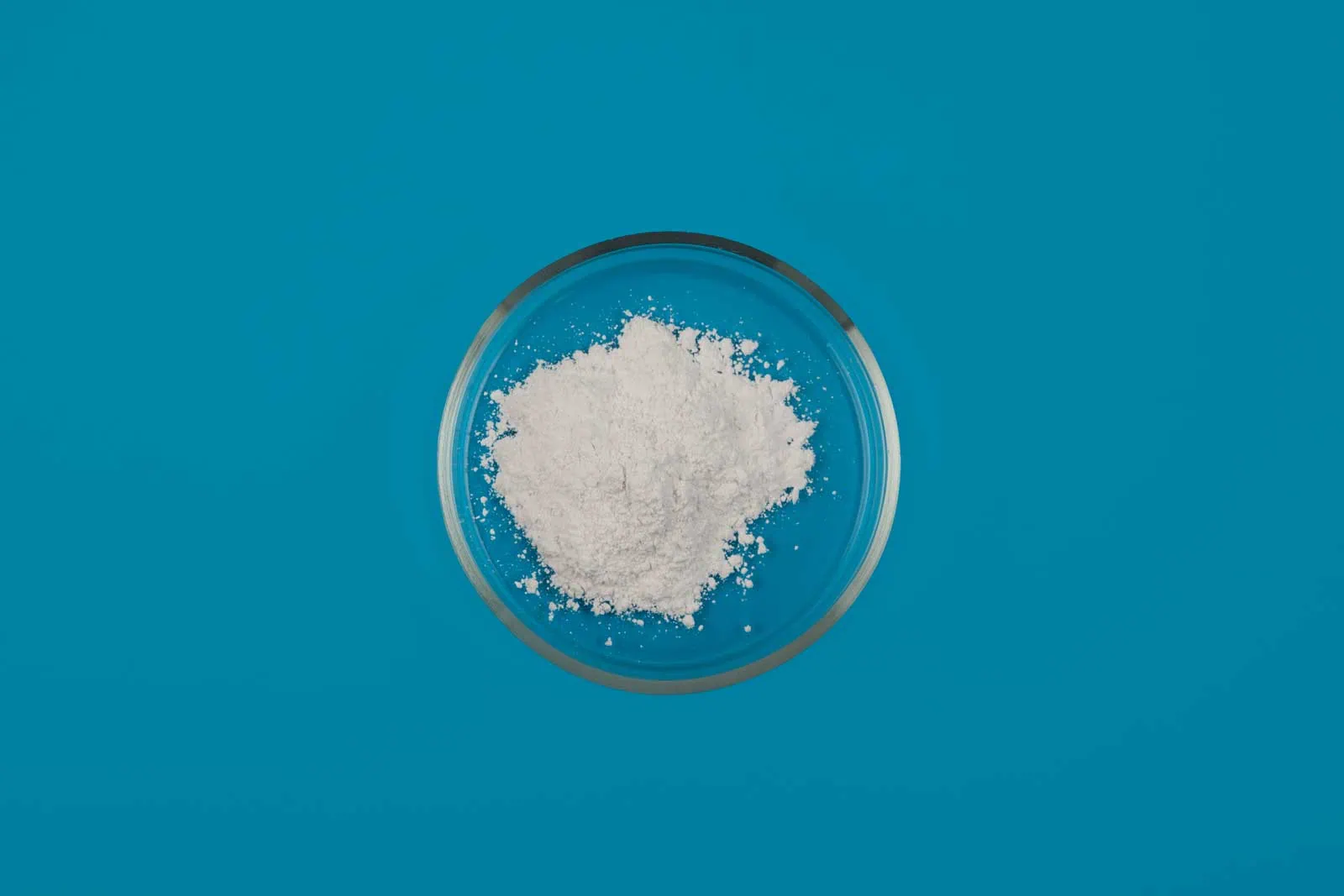

Read Full Blog PostHydrophobic Silica – Free Flow & More

Hydrophobic silicas comprise a unique group of materials that feature many types of advantageous properties and attributes. Their features make them suitable for a wide […]

Read Full Blog PostColloidal Silica vs. Fumed Silica

Applied Material Solutions offers a variety of industrial chemical products. In addition to colloidal silica, we provide a selection of antifoams and defoamers, hydrophobic treated […]

Read Full Blog PostPrivate Label Capabilities

When you’re looking to add a new product offering under your brand, there are several logistical considerations to make on how to bring it to […]

Read Full Blog PostBenefits of Silicone Antifoams

What is a Silicone Antifoam? A silicone antifoam is typically made of hydrophobized silica finely dispersed within silicone fluid. This compound is often stabilized in […]

Read Full Blog PostFoam Control in Fermentation

Managing conditions that cause air entrainment or foam formation is vital to agribusinesses and food processors. Air entrainment and foam formation can be caused by […]

Read Full Blog PostWater Treatment: General Resources

Water treatment is an essential but often complicated process. Water must be able to move smoothly through the filtration system to ensure productivity and reduce […]

Read Full Blog PostUnderstanding the Chemistry of Antifoams and Defoamers

Both antifoams and defoamers are used for foam control. Given their similarities in function, they often have similar chemistries. The main difference between them is […]

Read Full Blog PostAn Introduction to Silicone Emulsions

What Are Silicone Emulsions? Silicone emulsions are non-toxic and heat-stable compounds that are produced by dispersing silicone oil in a liquid, typically water. This process […]

Read Full Blog PostIndustry Spotlight: Water Treatment

Water treatment requires both defoamers and antifoams to prevent foaming and air entrapment that commonly occurs in these applications. Without these additives, the treatment process […]

Read Full Blog PostIndustry Spotlight: Wet & Dry Corn Milling for Fuel Ethanol Production

Foam can cause problems in many industrial processes. That’s why industry professionals utilize antifoams and defoamers to mitigate foam production and accumulation. In the renewable […]

Read Full Blog PostIndustry Spotlight: Fermentation

Industrial fermentation can generate significant quantities of foam due to the generation of carbon dioxide as a byproduct. Many industries turn to antifoam and defoaming […]

Read Full Blog PostKey Considerations for Selecting an Antifoam/Defoamer

Foam is created when gas is introduced and trapped within a solution that contains surfactants. It can consist of large bubbles at the surface of […]

Read Full Blog PostFoam Control Solutions for the Food & Beverage Industry

Foam is produced when gas (e.g., air) is added and becomes stabilized within a liquid (often water) containing impurities and surface-active agents (surfactants). The molecules […]

Read Full Blog PostWhy Should I Use Water-Based Defoamers?

Defoamers play a critical role in ensuring foam does not affect the quality of products and processes during industrial applications. They are available in many […]

Read Full Blog PostDon’t Passover Our Antifoams

Many types of foods and ingredients foam during the production process. If foaming is permitted, it can alter the product’s appearance, manufacturing time, quality or […]

Read Full Blog PostBenefits of Hydrophobic Silica

Hydrophobic silicas are a unique class of materials with a wide variety of functional attributes and beneficial properties making it ideal for numerous applications ranging […]

Read Full Blog PostWhat to Look for in a Foam Control Supplier

Antifoams and defoamers are vital for the safe, efficient operation of processes in a multitude of industries. Finding an experienced foam control supplier can save […]

Read Full Blog PostHow Do Antifoaming Agents Work

For most fluid systems, foam control is a challenge to overcome. Pure liquids do not foam. In an aqueous system, contaminants such as surfactants, proteins, […]

Read Full Blog PostWhat Is a Defoamer?

For most fluid systems, foam control is an interesting challenge to overcome. Pure liquids do not foam or will not form a stable foam. In […]

Read Full Blog PostTop 4 Tips for Proper Antifoam Use

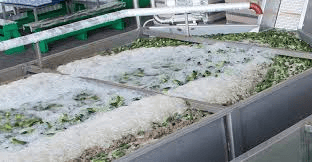

The formation of foam in aqueous processes and products—such as flume water for the transport of vegetables—can hinder or halt many industrial processing operations.

Read Full Blog PostDefoamers for the Pulp & Paper Industry

Foam in the Pulp & Paper Industry Lignin, rosin and fatty acid soaps, and hemicellulose are commonly formed during the pulping process, resulting in high […]

Read Full Blog PostWhat You Need to Know About Brown Stock Washing Defoamers

Brown stock washing is a complex, dynamic process in which dirty wash water or weak black liquor (dissolved organic and inorganic material obtained from the […]

Read Full Blog PostAll About Hydrophobic Treated Silica Products

Applied Material Solutions (AMS) is a Wisconsin-based company that manufactures high-quality hydrophobic treated silica products, including both precipitated and fumed varieties. By leveraging our unique […]

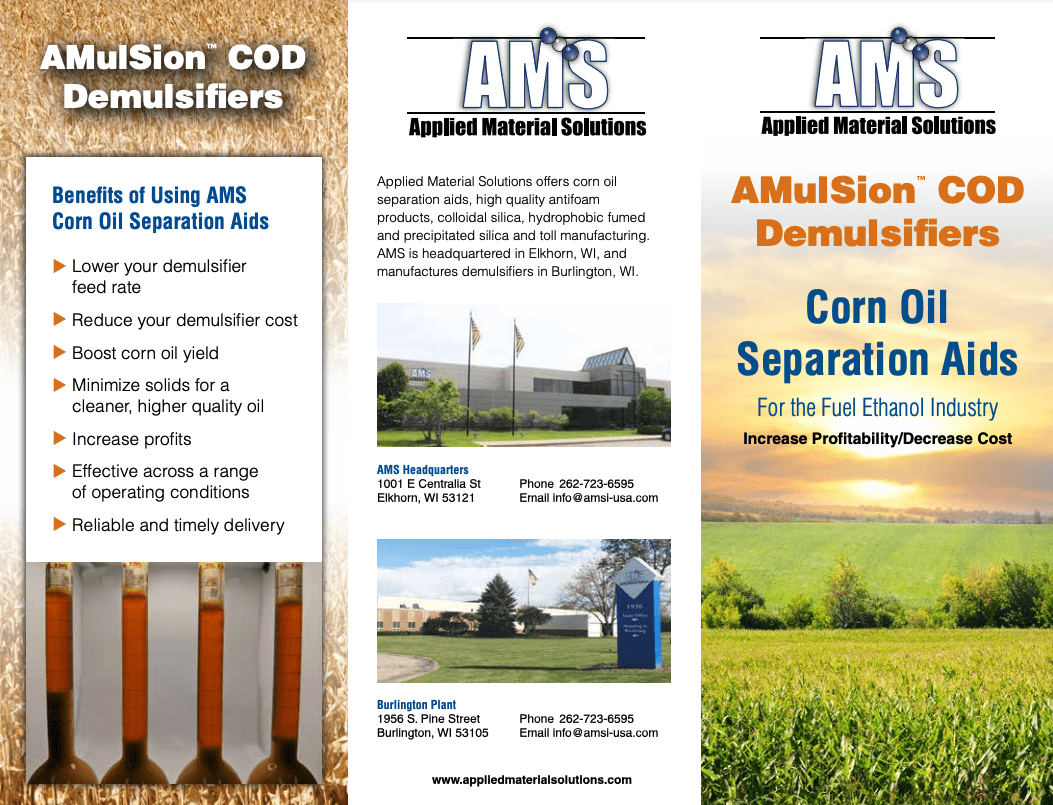

Read Full Blog PostHow it Works: Corn Oil Demulsifiers

Corn oil plays a central role in maintaining the profitability of today’s fuel ethanol facilities. Corn oil demulsifiers serve to improve oil release during the […]

Read Full Blog Post